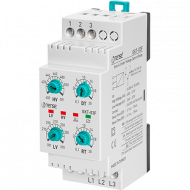

Caractéristiques

■ Conception compacte

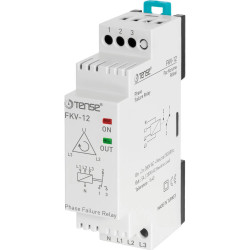

■ Surcharge/perte de Phase/protection du Rotor bloqué

■ Affichage précis du courant de fonctionnement (le courant le plus élevé de L1 et L3) via l'affichage LED du panneau avant

■ Lorsque le voyage se produit, la cause est affichée sur la fenêtre LED

■ Protection contre la perte de Phase (3 secondes)

■ Application pratique: utilisation sélective de monophasé (1P) et triphasé (3P) par commutateur DIP.

■ Sortie de contact optionnelle [échec-sécurité (N)/non-sécurité (R)]: simplifier le réglage de l'état de contact

■ Installation facile grâce au Rail Din et au montage sur panneau

Utilisé pour

-Électromoteur à basse tension (niveau 600V)

Relais de protection

-Démonter le relais de courant de la montre

-Remplacement alternatif du relais existant

Protection

Article de protection temps de fonctionnement (déclenchement)

Surintensité = O-TIME

Perte de Phase = 3 sec.

Rotor bloqué = après le temps D (courant de fonctionnement> 200% du courant réglé)

Ensemble

Une fois l'installation terminée, les réglages sont les suivants.

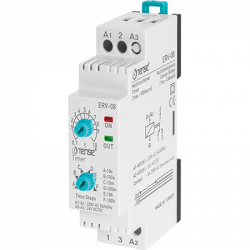

Bouton de réglage: D-TIME (temps de retard) régler deux à trois secondes de plus que le temps de démarrage du moteur.

Bouton de réglage: O-TIME (temps de fonctionnement en cas de surintensité) réglé moins que le temps d'endurance du moteur en cas de surintensité.

Bouton de réglage: charge (courant nominal) réglée sur 110% du courant nominal du moteur inférieur à 120% de son courant de fonctionnement

Indication de la Cause du voyage

Menu de Configuration

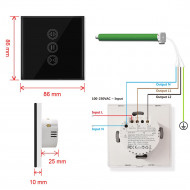

Spécifications

Gamme actuelle ............ : Type05) 0.5-6A

Type30) 3-30A

Type60) 5-60A

TYpe120) 10-120A

Type600) utiliser un externe

CT (secondaire 5A) sur 120A avec 05 type.

Tension de fonctionnement (Un). : Type220) 180-260VAC

Fréquence de fonctionnement... : 50/60Hz

Puissance de fonctionnement ........... : <2W

Température de fonctionnement: -20 ℃ · · · · · · + 55 ℃

Attente (t).............. : Temps D 1-30s

Temps O 1-10s

Ensemble asymétrique ............. : % ± 5

Contact ..................... : Charge résistive 5A 250VAC

Diagrammes de connexion .. : Rail Din de 35mm (D) ou

Panneau (P)

Dimensions

Construction

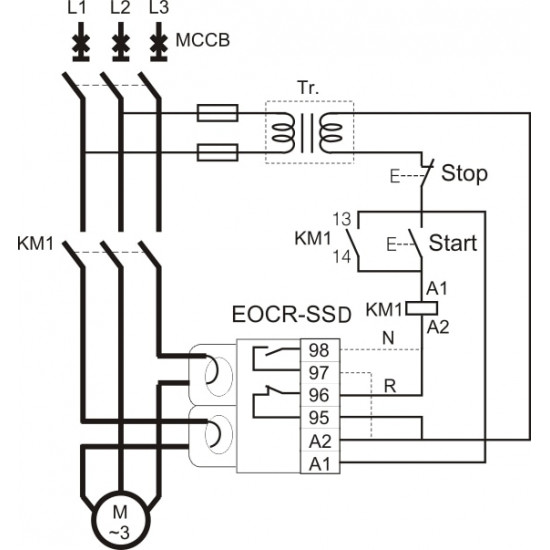

Schéma de connexion

- Stock: Rupture de stock

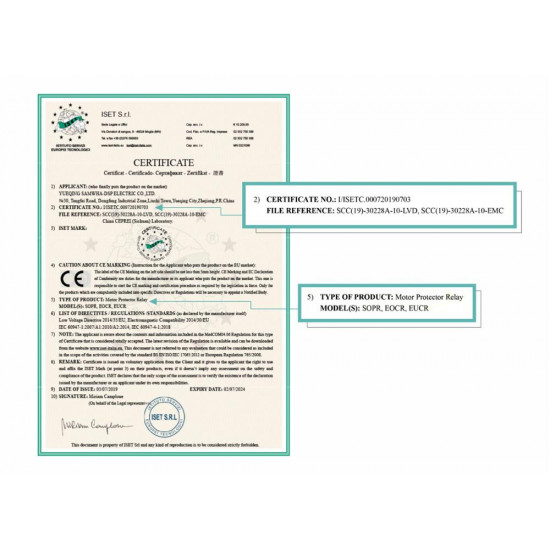

- Modèle: EOCR-SSD12000

- UGS: sesdz-225

-240x375h.png)

-250x250h.png)